Reducing Heat Loss in Pipeline Transportation with Aerogel Blankets in Petrochemical Industry | SA450

Mar 29,2023

- What is an aerogel blanket and why is it being used as an insulation material in the petrochemical industry?

- How does it compare to traditional insulation materials?

- Can you give an example of its application in the industry?

- What is the potential market size for aerogel in the oil and gas transmission pipeline industry?

Here is the Answers.

In recent years, Aerogel blanket has been widely used as a new type of insulation material in the petrochemical industry for oil and gas transmission, steam pipelines, and process pipelines, effectively reducing heat loss during the transportation of pipeline media.

Currently, materials such as calcium silicate, composite silicate, and rock wool are mainly used for pipeline insulation. The thermal conductivity of these insulation materials will increase significantly with the rise of environmental temperature and humidity. To meet the requirement of not exceeding the maximum allowable heat loss, it is necessary to increase the thickness of the insulation material. Using a thicker insulation layer will have a significant impact on the transportation, construction, and use space of the material.

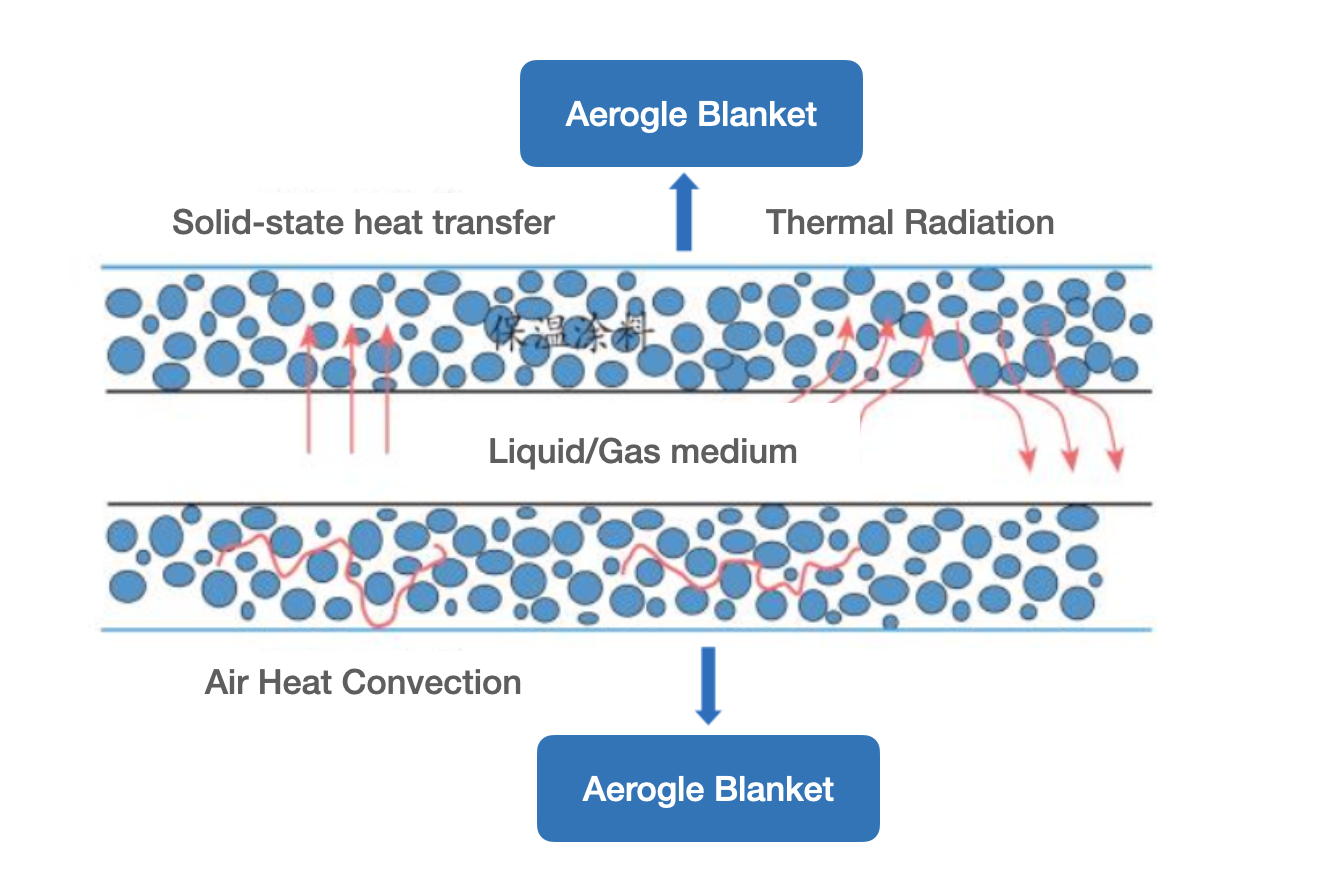

Therefore, adopting technologically advanced and efficient insulation materials for energy-saving renovation of thermal pipelines, reducing the thickness of the insulation layer, and reducing pipeline heat loss is an important area to overcome in thermal pipeline energy-saving insulation. The pore size of aerogel is smaller than the average free path of air molecules under normal pressure, which can make air molecules in the aerogel pore nearly static, avoiding convective heat transfer of air.

The very low volume density of aerogel and the bending path of its nanometer network structure also prevent gaseous and solid thermal conduction, and the infinite number of cavity walls can reduce heat radiation to the minimum. Through three aspects of joint action, it almost blocks the path of heat transfer, making aerogel achieve outstanding insulation effect, even lower than the thermal conductivity of static air at normal temperature of 0.025W/(m·K), reaching below 0.013W/(m·K).

Compared with traditional insulation materials, the thermal conductivity of silica aerogel insulation blanket is only 1/3 to 1/5 of traditional insulation materials, and its thermal insulation capacity is 2 to 8 times that of traditional materials. It has excellent fire resistance and water resistance, as well as good tensile, compressive strength, and chemical stability.

According to the paper <Application and Performance Analysis of Silica Aerogel Insulation Blanket>, the Tower Refinery of Sinopec used traditional type III high-temperature glass wool blanket insulation material for atmospheric coking equipment, and the subsequent pipeline insulation structure was reformed using silica aerogel insulation blanket + single-sided aluminum foil fiberglass cloth insulation material combination.

The paper shows through comparative analysis and calculation before and after the transformation of high-temperature pipelines that:

(1) after using silica aerogel insulation blanket as a new type of insulation material, heat loss was reduced by 34.66%, and the energy-saving effect was significant;

(2) silica aerogel insulation blanket as a new type of insulation material has obvious advantages in insulation performance compared with traditional insulation materials, particularly in terms of a significant reduction in temperature difference between the starting and ending points of the thermal pipeline and a more than 50% reduction in insulation layer thickness compared with traditional insulation materials.

Therefore, silica aerogel insulation blanket, as a new type of insulation material, has properties such as fire resistance, waterproofing, and ultra-low thermal conductivity, and has a long service life, making it an ideal choice for high-temperature pipelines in refineries.

Taking oil and gas transmission pipelines as an example, according to the President of the China Federation of Industrial Economics and former Minister of Industry and Information Technology, in 2021, the total length of China's long-distance oil and gas pipelines, including domestic and foreign pipelines, reached 165,000 kilometers. Generally, the diameter of oil and gas pipelines ranges from 15 millimeters to 1500 millimeters, and we will take 600 millimeters, that is, 0.6 meters for calculation. According to the paper <Progress in the Preparation of SiO2 Aerogel Fiber Composite Materials and their Applications in the Field of Building Energy Conservation>, a 20-millimeter aerogel blanket is required for thermal insulation of oil and gas pipelines. Therefore, it can be calculated that the cross-sectional area of aerogel blanket material used for oil and gas pipeline insulation is about 0.04 square meters, and the total volume is about 6.42 million cubic meters. Based on the current market price of aerogel of 10,000 yuan/cubic meter, the total market space can reach 64.2 billion yuan.

In 2021, assuming a share rate of 1%, the market space of aerogel in oil and gas transmission pipelines is about 640 million yuan(approximately 99.4 million US dollars), corresponding to a demand of 64,000 cubic meters of aerogel. According to the "14th Five-Year Plan for the Modern Energy System", issued by the National Development and Reform Commission and the National Energy Administration, it is estimated that the scale of the national oil and gas pipeline network will reach around 210,000 kilometers by 2025. It can be predicted that by 2025, the total market space of aerogel in the oil and gas transmission pipeline industry can reach 81.7 billion yuan. Assuming that the share rate increases to 3%, the market size of aerogel in the oil and gas transmission pipeline can reach about 2.45 billion yuan, corresponding to a demand of 245,000 cubic meters of aerogel. If the share rate increases to 15%, the market size of oil and gas transmission pipeline can increase to 12.3 billion yuan, corresponding to a demand of 1.23 million cubic meters. The above calculations only consider oil and gas transmission pipelines and do not take into account refinery steam pipelines and process pipelines, etc. If these are considered, the market space will be even larger.

According to the introduction by the chairman of the China Federation of Industrial Economics and former Minister of Industry and Information Technology, China's oil and gas long-distance pipelines, including domestic and foreign pipelines, had a total length of 165,000 kilometers in 2021. Generally speaking, the diameter of oil and gas pipelines ranges from 15 mm to 1500 mm. Taking 600 mm as an example, which is equivalent to 0.6 meters. According to the paper "Progress in the Preparation of SiO2 Aerogel Fiber Composite Materials and Their Application in the Field of Building Energy Conservation", a 20 mm aerogel blanket is required for thermal insulation of oil and gas pipelines. Therefore, it can be calculated that the cross-sectional area of aerogel blanket material used for thermal insulation of oil and gas pipelines is approximately 0.04 square meters, and the total volume is approximately 6.42 million cubic meters.

Based on the current market price of aerogel of 10,000 yuan/cubic meter, the total market space can reach 64.2 billion yuan (approximately 9.94 billion USD). In 2021, assuming a share rate of 1%, the market space for aerogel in oil and gas transportation pipelines is approximately 640 million yuan (approximately 98.9 million USD), corresponding to a demand of 64,000 cubic meters of aerogel.

According to the "14th Five-Year Plan for the Development of a Modern Energy System" issued by the National Development and Reform Commission and the National Energy Administration, it is estimated that the scale of the national oil and gas pipeline network will reach about 210,000 kilometers by 2025. Therefore, it can be estimated that the total market space for aerogel in the field of oil and gas transportation pipelines will reach 81.7 billion yuan (approximately 12.68 billion USD) by 2025. Assuming a share rate of 3%, the market size for aerogel in oil and gas transportation pipelines can reach approximately 2.45 billion yuan (approximately 380 million USD), corresponding to a demand of 245,000 cubic meters of aerogel.

If the share rate increases to 15%, the market size for oil and gas transportation pipelines can increase to 12.3 billion yuan (approximately 1.91 billion USD), corresponding to a demand of 1.23 million cubic meters. The above calculations only consider oil and gas transmission pipelines and do not include refinery steam pipelines and process pipelines.

Find out our Product, Find out the answer.