Aerogel Solves Big Pain-Point of Ternary Battery Safety Issue in the Automotive Industry

Jan 04,2022

A Firewall in your Car - Aerogel

Aerogel materials can not only solve the safety problems of the current ternary battery system and other battery systems, but also can play a flame retardant performance applied to the automotive interior materials.

Aerogel Solve the Pain-Point of Ternary Battery Safety Issue

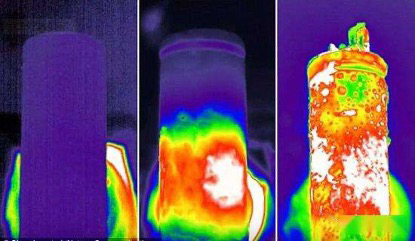

When the battery for Electric Vehicle output power for a long time, the chemical reaction in the battery for a long time will make the battery obviously hot, there is a risk of combustion and explosion. Traditional battery core modules are used to separate the batteries from each other by using plastic spacers, which are not practically useful. This is not only heavy but also cannot play a protective role, and it is easy to cause temperature of the battery too high to dissolve of the spacers, catch fire and other problems. The existing protective mat has a simple structure and is easily deformed, which makes it unable to contact with the battery pack comprehensively, and it does not play a good heat insulation effect when the battery is seriously heated, and the appearance of aerogel composite material is expected to solve this pain point.

Aerogel Play a good heat insulation

Binary Batteries Require Higher Safety Performance

Binary Batteries advantages lie in two aspects: Energy Storage Density and Low Temperature Resistance:

1) Energy storage density, ternary lithium battery energy density is 170-200Wh/kg, the energy density will be further enhanced later, while the lithium iron phosphate energy density is 140-160Wh/kg;

2) low-temperature performance, for ternary lithium battery the lower limit temperature use is -30 °C (-22 °F), while for lithium iron phosphate is -20 °C (-4 °F), in the same low-temperature conditions, ternary lithium battery winter attenuation of less than 15%, lithium iron phosphate attenuation up to 30% or more. However, due to the higher energy density of ternary batteries, the stability and safety of the battery is relatively poor, and it relies more on high-performance flame retardant materials to enhance the safety performance of the ternary battery system.

Ternary Batteries Account for the Major Share

Data show that from January to July 2020, China's power battery vehicle installation accumulated 22.5GWh. Among which 15.9GWh of ternary batteries were installed, accounting for 70.6% of the total installed capacity; 6.5GWh of lithium iron phosphate batteries were installed, accounting for 28.8% of the total installed capacity, and global shipments of ternary cathodes are expected to reach 1.5 million tons in 2025.

Global ternary cathode shipments and forecast, 2016-2025 (unit: 10,000 tons)

As emerging of Aerogel will Improve Safety of Power Battery

Aerogel composites material as flame retardant materials have the advantages of light weight, excellent flame retardant performance and good environmental performance compared with traditional flame retardant materials.

At present, there are mainly two kinds of heat insulation and flame retardant materials used in the battery core module of electric vehicles:

1) Plastics PP, ABS, PVC, etc., of which ABS engineering plastics are the main, usually add flame retardants into PP, ABS and other plastics to make flame retardant plastics;

2) Fireproof mats made of glass fiber, ceramic fiber wool and other fireproof materials. As an emerging material, the aerogel composites made by combining aerogel and engineering materials have exceptional adiabatic and flame retardant properties. SiO2 aerogel glass fiber mat composites, which can achieve thermal conductivity below 0.017W/m-k at room temperature of 25 °C (77 °F)and between 0.047 and 0.066W/m-k at high temperature of 600 °C (1,112 °F), can increase the high temperature resistance of battery pack to more than 800 °C (1,472 °F).

Link: Sino-Aerogel CA500 Electric Vehicle (EV) Use Thermal Insulation

Aerogel Ceramic Composite Fiber Materials

High temperature Protector - Aerogel

The aerogel composite material can withstand the instantaneous impact of high temperature energy caused by the short circuit of the battery pack, which can better solve the safety problem of power battery. According to the requirements of "Safety Technical Conditions of Electric Buses", the rechargeable energy storage system (or installation compartment) should be isolated from the passenger compartment by using flame retardant insulation material, the burning performance of which should meet the requirements of Class A non-combustion as stipulated in GB8624-2012, and the thermal conductivity should be less than or equal to 0.04W/(m·k) at 300 °C (572 °F). Each surface of its silica aerogel felt layer is connected by high-silica oxygen glass fiber cloth layer wrapping, and the opening of the wrapping is connected by high-silica oxygen thread.

Flame retardant insulation material - Aerogel

Demand booming of aerogel composites material

The material achieves the performance index of UL94 V0 level of non-combustion required by EV, the thermal conductivity at 400 °C (752 °F) is less than or equal to 0.04W/(m·k), and can work for a long time at 800 °C (1,472 °F) high temperature, which meets the condition of lithium-ion power battery cells in the event of impact short circuit or overcharge heat spontaneous combustion, isolates the high temperature energy released from the faulty battery cells instantly, making the battery cells spontaneous combustion fire no longer expand extension.

Aerogel composites material cover protect EV battery pack

The potential size of aerogel composites in the China electrical vehicle market is expected to be about $628 million in 2025. According to Aspen Aerogel 2019 annual report, the average price of aerogel material in recent years is about US$30.00 per square meter, and each EV needs about 2-5 square meters of aerogel composites, then each new energy vehicle needs an average of US$105.00 of aerogel composites material. According to the "Electric Vehicle Industry Development Plan (2021-2035)", by 2025, the sales volume of electrical vehicles will reach about 20% of the total sales volume of EV, that CAGR will reach more than 30%.

Aerogel composites material for EV Bus insulation layer

Reduce Fire Hazard with Aerogel composites material

The potential size of aerogel composites in the global EV market is expected to be about $1.575 billion in 2025 and reach $3.150 billion in 2030. Electrical vehicles are also the global mainstream development direction, and according to the planning target of mainstream car companies, the corresponding global sales will be close to 15 million units in 2025, and will reach 30 million units in 2030E.

The aerogel flame retardant compound not only has better flame retardant performance and hydrophobic property, but also can enhance the strength of the material matrix to improve its toughness. After specific modification, silica aerogel can have a large specific surface area, and it has a strong interfacial adhesion with polymer matrix such as plastic and rubber, which improves the dispersion and fluidity of the compound aerogel flame retardant in the polymer melt and enhances the flame retardant effect, and the thermal stability and thermal decomposition temperature of the modified rubber have been improved to different degrees.

Application of aerogel flame retardant materials in bus

The aerogel materials can be used together with flame retardants to produce flame retardant materials with superior performance, and the potential market space is also large. Aerogel flame retardant materials can also be widely used in different scenarios, such as different parts of the vehicle, such as seat flame retardant lining and body flame retardant lining, which can replace the traditional thermal insulation flame retardant materials. Its flame retardant can curb the spread of fire, and its low smoke density feature will reduce the lethality of fire, significantly reducing the fire hazard and protecting the safety of passengers.

BYD ADL Enviro200EV XLB ultra-long EV Bus manufacture in New Zealand