Aerogel - An Innovative Insulation Material for Sustainable Building!

Mar 18,2022

Intro

Building insulation can help to keep your home comfortable and energy-efficient, but it also needs to be as safe as possible. Traditional insulators such as fiberglass are known to contain asbestos, which can cause lung cancer and mesothelioma if inhaled regularly over time. Aerogel material insulation is both cost-effective and completely safe to breathe in the long term, making it a superior alternative for anyone looking to improve their home insulation this season. The full spectrum of aerogel material benefits are listed below, but first we will discuss how these unique characteristics make aerogel an ideal insulation choice overall.

Building Insulation with Aerogel Material

Building insulation can help to keep your home comfortable and energy-efficient, but it also needs to be as safe as possible. Traditional insulators such as fiberglass are known to contain asbestos, which can cause lung cancer and mesothelioma if inhaled regularly over time. Aerogel material insulation is both cost-effective and completely safe to breathe in the long term, making it a superior alternative for anyone looking to improve their home insulation this season. The full spectrum of aerogel material benefits is listed below, but first, we will discuss how these unique characteristics make aerogel an ideal insulation choice overall.

Aerogel Definition

There is also a widespread allusion to the birth of aerogel, which originated from a bet between Dr. Samuel Stephens Kistler and Charles Learned - to see who could replace the liquid in the gel with gas without changing the solid structure.

It is an all-known fact that if the liquid in a gel is separated from the solid by direct evaporation, the strong capillary forces will inevitably lead to shrinkage and structural collapse of the solid. After continuous exploration, Dr. Kistler finally solved this world problem perfectly by using alcohol supercritical drying technology. In this way, the world's first aerogel, silica aerogel, was born. Silica aerogel has very low density (0.16 g/cm3), high thermal insulation performance (up to 3 times higher than rock wool), good chemical stability, non-toxicity and can be used as adsorbent material or catalyst carrier. Aerogels are also known as solid smoke or solid air. They are made up of 99% air and look like white cotton candy or snow after being compressed into small pellets. The most amazing characteristic of aerogels is their ability to trap air inside their microstructure. This characteristic makes them extremely lightweight while at the same time having a great insulating effect. Due to these unique properties, they have been widely applied in many fields such as building insulation materials, filters for hazardous gases and liquids and drug delivery systems.

Uses of aerogels in building insulation

Sustainable buildings can be defined as efficient buildings from the point of view of maintenance and operation costs, and of which value increases in time, through a positive impact on the natural and social environment. The aim of rendering buildings sustainable can be achieved only by the production of new advanced materials, and by using them, especially at the glass surfaces, for more resistant envelopes at different external actions which may increase considerably the durability period of a building and may increase the energy efficiency through high-level thermal insulation. Explore the possibility of the use of Aerogels as a building material with reference to its chemical, physical characteristics, and performance. It is supposed to be an expensive method initially but is more advantageous, considering the low costs afterward, mainly, because of reduced energy consumption. About the chemical adaptation of Aerogels for optical applications, chemical adaptation of Aerogels to thermal insulation and its various applications in Building Industry. The study concludes that Aerogels are suitable for many uses in buildings, such as: insulating walls and roofs; insulating floors; lining pipes; fireproofing walls and ceilings; soundproofing walls and ceilings; lining hot water tanks (to reduce heat loss); lining air conditioning ducts (to reduce heat loss); lining refrigerators (to prevent frost build-up).

Traditional insulation materials in building have such weakness,

Low thermal insulation efficiency, energy-saving and emission reduction effect is not significant. Poor environmental performance, difficulty to dispose of the product after disposal, and pollution of the environment. Poor hydrophobic performance, large deformation coefficient, short service life. Part of the material is not fireproof, and easy to release toxic and harmful gases at high temperatures. The life of polymer materials is short, can not meet the needs of long-term insulation. The core component of Aerogel, is to use silica as raw material and modified into fine particles, then by high temperature, vacuum dehydration and supercritical treatment method gelization. The aerogel in accordance with its characteristics after expansion, compression performance about ten times of normal solid material density.

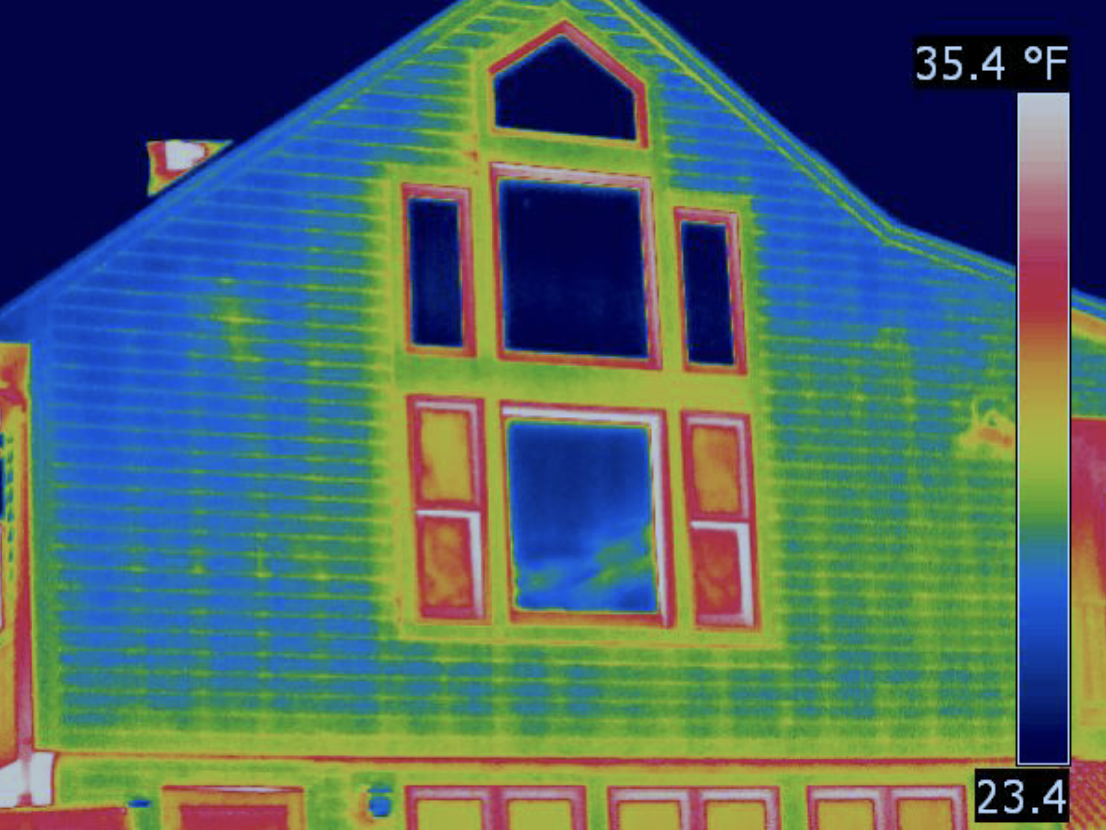

Thermal bridging in a typical residential building.

How does aerogel help you save energy?

Aerogels may have a thermal conductivity smaller than that of the gas they contain. This is caused by the Knudsen effect, a reduction of thermal conductivity in gases when the size of the cavity encompassing the gas becomes comparable to the mean free path. Effectively, the cavity restricts the movement of the gas particles, decreasing the thermal conductivity in addition to eliminating convection. For example, thermal conductivity of air is about 25 mW·m−1·K−1 at STP and in a large container, but decreases to about 5 mW·m−1·K−1 in a pore 30 nanometers in diameter.

Aerogel contains particles that are 2–5 nm in diameter. After the process of creating aerogel, it will contain a large amount of hydroxyl groups on the surface. The hydroxyl groups can cause a strong reaction when the aerogel is placed in water, causing it to catastrophically dissolve in the water. One way to waterproof the hydrophilic aerogel is by soaking the aerogel with some chemical base that will replace the surface hydroxyl groups (–OH) with non-polar groups (–OR), a process which is most effective when R is an aliphatic group.

One way aerogels help save energy is by using less cooling and heating systems to produce a comfortable indoor environment. In building insulation, an aerogel blanket is made of thousands of interconnected nodes that allow air to flow in and out. With a much thinner profile than fiberglass or foam-based materials, aerogels make great thermal insulation because they have several properties including high surface area, small pore size and exceptional flexibility. These properties help reduce heat transfer across walls, windows and floors. Aerogels are also used as soundproofing material due to their porous nature and ability to absorb sound waves.

Additionally, aerogels can be used as a catalyst support, which allows them to promote chemical reactions at lower temperatures. They can also be used as catalysts themselves; silica-based aerogels react with many organic molecules at room temperature and pressure. Aerogel catalysts are being explored for use in areas such as fuel cells, biofuel production and petroleum refining.

Where can aerogels be used?

Roof, floor, and inside wall, outside wall. Aerogels are also good insulators. They have been shown to have an R-value of up to 9.5 per inch (25 cm) in thickness. In addition, aerogels can be used as thermal mass because they are very effective at storing heat energy and releasing it over time. This means that when you use aerogels in a building design that is exposed to sunlight during the day but gets cold at night, it will stay warm during those nighttime hours.

What are the benefits of using aerogels?

Sino-Aerogel SA450 Thermal Insulation Material Panel Aerogel, Low thermal conductivity, good insulation performance, thin insulation layer thickness, space-saving. Good fireproof and hydrophobic performance, long service life. Safe and environmentally friendly, harmless to the people. Porous structure, high specific surface area, sound insulation and noise reduction, creating a comfortable environment. Easy to cut, convenient construction, reduce construction cost. Insulating performance is high, good thermal insulation and sound insulation effect. Strong adaptability, aerogels can be made into various shapes according to different needs of customers. And it can also be combined with other materials such as glass wool, rock wool and so on in order to achieve better thermal insulation effect. The performance of aerogels will not change even if they are wet or in an environment with high humidity and temperature fluctuation.